Beauty brands face increasing pressure to deliver high-quality products while managing complex supply chains efficiently. Integrated manufacturing solutions, such as enterprise resource planning systems, help you streamline beauty supply chains by connecting processes and eliminating inefficiencies. These systems enhance workflows by automating routine tasks, reducing errors, and providing real-time data for faster decision-making. They also optimize formulas for consistent product quality, ensuring every batch meets your standards. With effective ERP solutions, you gain the ability to manage inventory accurately, avoid waste, and respond swiftly to market demands.

Understanding the Challenges in Beauty Supply Chains

Raw Material Sourcing and Sustainability

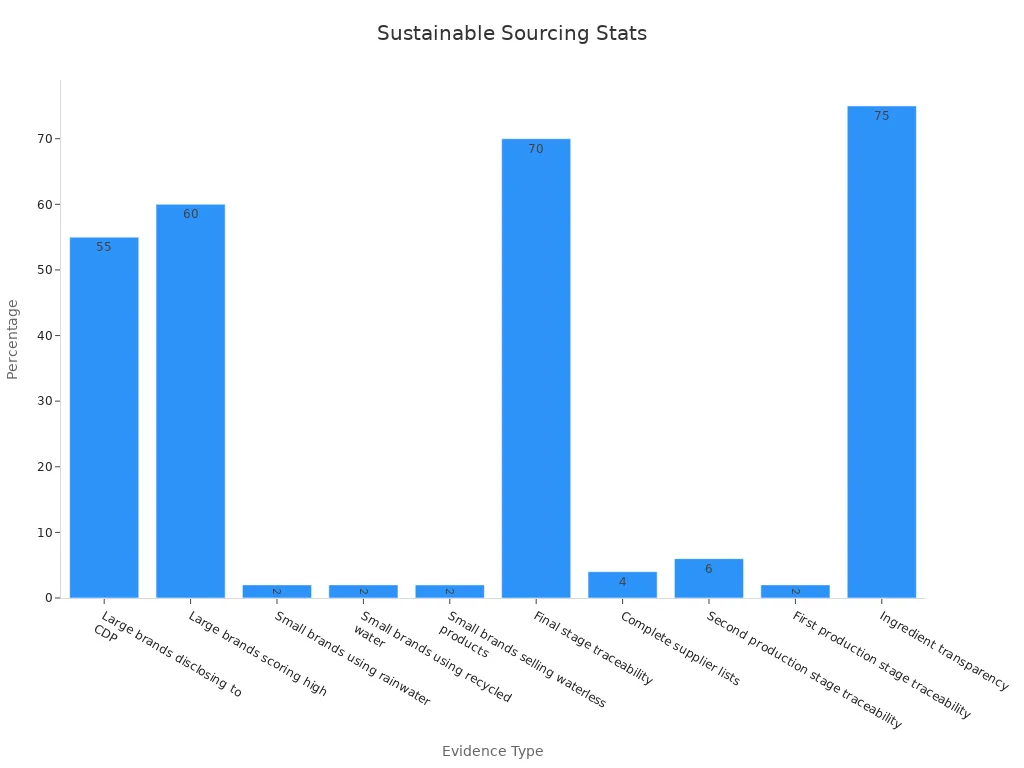

Sourcing raw materials for cosmetics presents unique challenges. You must ensure that ingredients meet quality standards while addressing growing consumer demand for sustainability. Many brands now prioritize sustainable practices, such as using natural or recycled materials. 하지만, 오직 4% of brands publish detailed supplier lists, and just 2% trace their raw materials back to the first production stage. This lack of supply chain transparency makes it difficult to verify the ethical and environmental impact of sourcing practices.

The beauty industry is also shifting toward waterless products and natural emollients to reduce environmental impact. Yet, 오직 2% of small brands use rainwater or recycled water in production. 결과적으로, achieving sustainability goals requires significant effort and innovation.

Regulatory Compliance and Quality Standards

Navigating regulatory frameworks in the cosmetic supply chain can be complex. Regulations vary across regions, requiring you to adapt your processes to meet local standards. 예를 들어, organizations like the International Cooperation on Cosmetics Regulation (ICCR) work to harmonize guidelines globally, but differences still exist.

그만큼 clean beauty movement adds another layer of complexity. Consumers now expect transparency about ingredients and safety. Brands like Beautycounter lead the way by avoiding harmful substances and disclosing ingredient lists. 하지만, 72% of brands using fragrance ingredients do not reveal their exact composition, which can erode trust. Staying compliant while meeting consumer expectations is essential for success.

Demand Forecasting and Market Trends

Predicting demand in the cosmetics industry is challenging due to rapidly changing trends. Economic shifts, such as downturns, can reduce consumer spending on non-essential items. 또한, fluctuating raw material costs and trade policies affect pricing strategies.

The rise of e-commerce has transformed how consumers shop for cosmetics. You must adapt to these changes by leveraging data and analytics to forecast demand accurately. This approach helps you avoid product shortages and overproduction, ensuring your supply chain management remains efficient.

Logistics and Distribution Complexities

Managing logistics and distribution in the cosmetics industry presents unique challenges. You must ensure products reach customers quickly while maintaining quality. This process becomes even more complex when dealing with global markets. Factors like customs regulations, shipping delays, and temperature-sensitive products can disrupt operations.

Efficient logistics rely on tracking key performance metrics. These indicators help you identify bottlenecks and improve processes. 예를 들어, on-time delivery measures how often orders arrive as promised. Order fulfillment cycle time tracks the duration from order receipt to delivery. Inventory turnover shows how well you balance stock levels with sales. Supplier performance evaluates reliability based on delivery times, product quality, and responsiveness. The table below summarizes these metrics:

메트릭 | 설명 |

|---|---|

On-time delivery | Measures the percentage of orders delivered on or before the promised delivery date. |

Order fulfillment cycle time | Time taken from order receipt to delivery, including processing, manufacturing, and shipping time. |

Inventory turnover | Indicates how efficiently inventory is managed, reflecting the balance between stock levels and sales. |

Supplier performance | Evaluates reliability based on on-time delivery, product quality, and responsiveness. |

You also face challenges in managing distribution networks. Retailers, e-commerce platforms, and direct-to-consumer channels require different strategies. 예를 들어, e-commerce demands faster shipping and accurate tracking. Temperature-sensitive cosmetics, like creams or serums, need special handling to prevent spoilage during transit. Without proper supply chain management, these issues can lead to delays, increased costs, and dissatisfied customers.

To overcome these complexities, you should adopt integrated manufacturing solutions. These systems provide real-time data, helping you monitor shipments and optimize routes. By improving visibility, you can reduce delays and ensure products arrive in perfect condition. Streamlining logistics not only enhances efficiency but also strengthens customer trust in your brand.

How Integrated Manufacturing Solutions Streamline Beauty Supply Chains

Real-Time Data and Visibility

Real-time data plays a crucial role in improving supply chain visibility. It allows you to monitor every stage of the manufacturing process, from raw material sourcing to product delivery. With real-time tracking, you can identify bottlenecks, reduce delays, and make informed decisions quickly. 예를 들어, Cin7 uses real-time updates and automated processes to manage stock levels effectively. This approach enhances visibility across multiple sales channels and warehouses, 원활한 운영 보장.

Key metrics such as inventory levels, lead times, and shipment statuses provide actionable insights. Tools like the BatchMetrics QC/LIMS Module integrate quality control with production processes, offering real-time visibility for timely decision-making. By leveraging these systems, you gain better control over your supply chain and improve transparency and collaboration with stakeholders.

Advanced Inventory Management for Optimal Stock Levels

Effective inventory management ensures you maintain the right stock levels to meet customer demand without overstocking. Advanced systems use AI and data analytics to optimize inventory, reducing waste and improving efficiency. 예를 들어, the LEAFIO Inventory Optimization system increased sales by 15% and reduced excess stock by 8% within two months of implementation. These results highlight the importance of adopting modern inventory strategies.

Advanced inventory management tools also help you forecast demand accurately. By analyzing historical data and market trends, these systems predict future needs, allowing you to adjust stock levels proactively. This approach minimizes the risk of stockouts and overproduction, ensuring your supply chain remains agile and responsive.

Streamlined Production Processes with Automation

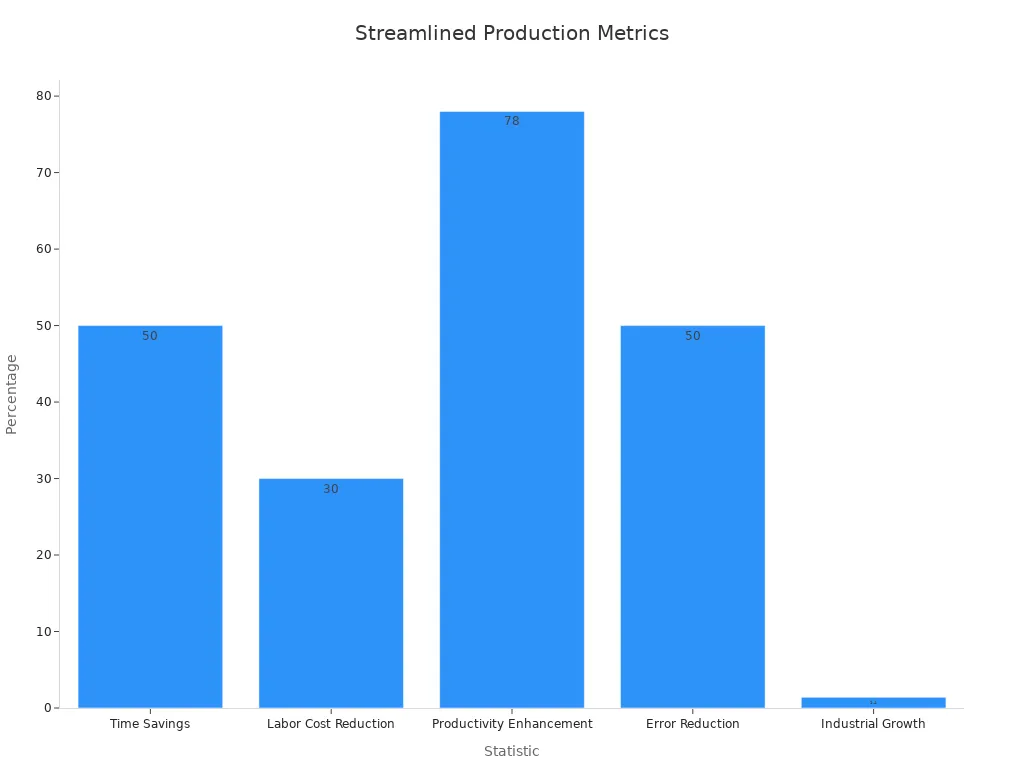

Automation transforms batch manufacturing by streamlining production processes and reducing manual errors. Automated systems handle repetitive tasks efficiently, saving time and lowering costs. According to industry data, 73% of IT leaders believe automation saves up to 50% of time, ~하는 동안 51% report cost reductions of 10% 에게 50%. These benefits make automation a valuable tool for optimizing manufacturing operations.

Incorporating automation and robotics into your manufacturing process enhances productivity and consistency. Automated systems ensure each batch meets quality standards, reducing variability and improving customer satisfaction. 또한, automation supports scalability, enabling you to meet growing demand without compromising efficiency.

By integrating automation into your production processes, you can achieve faster turnaround times and better resource utilization. This approach not only streamlines beauty supply chains but also positions your brand for long-term success.

Predictive Analytics for Demand Planning

Predictive analytics transforms how you plan for demand in the beauty industry. By analyzing historical data and current trends, these tools forecast future needs with remarkable accuracy. AI-powered models, 예를 들어, evaluate sales patterns and social media activity to identify emerging preferences. This insight allows you to adjust production schedules and inventory levels proactively, ensuring you meet customer expectations without overstocking.

The beauty sector has embraced predictive analytics to streamline beauty supply chains. AI algorithms now play a pivotal role in trend forecasting and inventory management. 그만큼 market for AI in beauty was valued at $3.27 10 억입니다 2023 and is projected to grow to $16.4 10 억으로 2033. This growth highlights the increasing reliance on data-driven decision-making. 이러한 도구를 활용하여, you can anticipate shifts in consumer behavior and align your manufacturing processes accordingly.

Predictive analytics also enhances supply chain visibility. Real-time data integration ensures you monitor inventory levels and production timelines effectively. This transparency reduces the risk of delays and helps you maintain optimal stock levels. 예를 들어, AI systems can predict seasonal demand spikes, enabling you to prepare for high-volume periods without compromising efficiency.

Enhanced Collaboration Across Stakeholders

Collaboration across stakeholders is essential for optimizing beauty supply chains. Integrated systems foster transparency and collaboration by connecting manufacturers, suppliers, and distributors. When everyone shares access to real-time data, decision-making becomes faster and more accurate. This alignment ensures that all parties work toward common goals, such as reducing lead times and improving product quality.

Technology plays a key role in enhancing collaboration. Cloud-based platforms allow you to share updates and insights with stakeholders instantly. These tools improve communication and reduce misunderstandings, 원활한 운영 보장. 예를 들어, a shared dashboard can display inventory levels, shipment statuses, and production schedules, keeping everyone informed and aligned.

Collaboration also drives innovation. By working closely with suppliers and manufacturers, you can develop new formulations and packaging solutions that meet market demands. This partnership approach accelerates product development and strengthens your brand’s competitive edge. 또한, transparent communication builds trust, fostering long-term relationships with stakeholders.

Integrated manufacturing solutions amplify these benefits. They streamline beauty supply chains by improving supply chain visibility and enabling seamless collaboration. When stakeholders work together effectively, you can achieve faster turnaround times, higher product quality, and better customer satisfaction.

Benefits of Integrated Manufacturing for Beauty Brand Fulfillment

Cost Savings Through Efficiency

Integrated manufacturing systems significantly reduce costs by streamlining operations and improving business efficiency. These systems optimize inventory management, 해운, and expense allocation, ensuring you allocate resources effectively. 예를 들어, advanced inventory tools predict stock levels accurately, helping you avoid overstocking or understocking. This approach reduces restocking costs by 10-30%, allowing you to reinvest savings into other areas of your business.

Efficient logistics also contribute to cost savings. Integrated systems optimize shipping routes and consolidate shipments, lowering transportation expenses. Volume discounts and faster delivery times enhance customer satisfaction, strengthening your position as a reliable fulfillment partner. 또한, strategic expense management minimizes wasteful spending, improving operational agility and boosting customer retention.

전략 | 설명 |

|---|---|

Efficient Inventory Management | Reduces overall restocking costs by 10-30% through better stock level predictions and informed purchasing decisions. |

Streamlined Shipping and Logistics | Lowers transportation costs via optimized shipping routes and volume discounts, enhancing customer satisfaction. |

Strategic Management of Expenses | Improves operational agility and reduces wasteful expenditure, leading to higher customer retention and brand loyalty. |

By adopting integrated manufacturing, you can achieve substantial cost savings while maintaining high standards of beauty brand fulfillment. These savings not only improve your bottom line but also allow you to invest in sustainability and ethical practices, further enhancing your brand’s reputation.

Improved Product Quality and Consistency

Integrated manufacturing ensures consistent product quality, a critical factor in building customer trust and loyalty. Quality management systems (QMS) play a vital role in maintaining high standards throughout the production process. These systems implement rigorous protocols for sourcing and testing raw materials, ensuring compliance with industry regulations. By prioritizing quality, you safeguard consumer safety and strengthen your market presence.

Regulatory compliance ensures product integrity and consumer safety.

QMS automation reduces defects and minimizes customer complaints.

Comprehensive quality assurance systems identify and mitigate potential hazards during production.

Consistent quality enhances customer satisfaction and sustains business momentum.

Automation within QMS further improves efficiency by streamlining quality checks and reducing human error. This approach positively impacts metrics like overall equipment effectiveness (OEE) and cost of quality. 예를 들어, automated systems ensure every batch meets safety guidelines, minimizing recalls and protecting your brand’s reputation.

Focusing on quality also supports sustainability and ethical practices. By using high-quality, responsibly sourced materials, you align with consumer expectations for eco-friendly products. This commitment not only enhances your brand image but also positions you as a leader in the beauty industry.

Faster Time-to-Market for New Products

Integrated manufacturing accelerates product development, enabling you to bring new products to market faster. A unified system eliminates data redundancies and process bottlenecks, streamlining every stage of production. This integration ensures seamless collaboration between teams, reducing delays and improving overall efficiency.

혜택 | 설명 |

|---|---|

A single integrated system increases speed by eliminating data redundancies and process bottlenecks. | |

Rapid Commercialization | A single source of truth platform allows for quick adaptation to changing consumer demands. |

Expedite products to market | End-to-end product development management enhances control and transparency, leading to faster market entry. |

AI-driven process optimization further enhances speed and efficiency. By analyzing production data, AI identifies areas for improvement, reducing material waste and energy use. This approach not only accelerates timelines but also supports sustainability and ethical practices. 예를 들어, predictive analytics can forecast demand spikes, allowing you to adjust production schedules proactively and meet market demands without delays.

Faster time-to-market gives you a competitive edge in the beauty industry. By responding quickly to emerging trends, you can capture consumer interest and establish your brand as an innovator. Integrated manufacturing ensures you stay ahead of the curve, delivering high-quality products that resonate with your audience.

Better Customer Satisfaction and Retention

Integrated manufacturing systems play a vital role in enhancing customer satisfaction. By streamlining operations, these systems ensure that you deliver high-quality products on time, every time. Customers value consistency, and when your products meet their expectations repeatedly, they are more likely to remain loyal to your brand.

Here’s how integrated manufacturing boosts customer satisfaction:

Fewer Delays in Delivery: Real-time data and optimized logistics ensure that orders reach customers promptly. Late deliveries can frustrate customers, but timely fulfillment builds trust.

Consistent Product Quality: Automated quality control systems reduce defects, ensuring that every product meets the same high standards. Customers appreciate reliability in the products they use daily.

Personalized Offerings: Advanced analytics help you understand customer preferences. By tailoring products to their needs, you create a more personalized experience.

팁: Happy customers are your best advocates. They not only return for repeat purchases but also recommend your brand to others, amplifying your reach.

Retention becomes easier when you focus on building strong relationships. Integrated systems allow you to track customer feedback and respond quickly to concerns. 예를 들어, if a customer reports an issue with a product, you can trace the batch and address the problem efficiently. This proactive approach shows customers that you value their input, strengthening their loyalty to your brand.

Scalability for Future Growth

Integrated manufacturing systems provide the flexibility you need to scale your operations as your business grows. Whether you’re expanding into new markets or launching additional product lines, these systems adapt to your evolving needs.

Here are some ways integrated manufacturing supports scalability:

Efficient Resource Allocation: Advanced planning tools help you allocate resources effectively, ensuring that you can handle increased production demands without overextending your capacity.

Automation for Higher Output: Automated processes allow you to produce more without compromising quality. This scalability ensures that you can meet growing customer demand.

Data-Driven Decision-Making: Predictive analytics guide your expansion strategy by identifying trends and opportunities. With accurate insights, you can make informed decisions about where to invest.

Feature | 혜택 |

|---|---|

Automation | Increases production capacity without adding significant labor costs. |

Cloud-Based Systems | Enables seamless integration across multiple locations. |

Predictive Analytics | Identifies growth opportunities and minimizes risks. |

메모: Scalability is not just about producing more. It’s about maintaining efficiency and quality as you grow. Integrated systems ensure that your operations remain streamlined, even as they expand.

By investing in scalable solutions, you future-proof your business. You can adapt to market changes, meet customer expectations, and seize new opportunities without disrupting your existing operations. This adaptability positions your brand for long-term success in the competitive beauty industry.

사례 연구: Success Stories in Beauty Supply Chain Optimization

울리: Reducing Lead Times with Real-Time Data

Oully has transformed its supply chain by leveraging real-time data to reduce lead times. By implementing advanced tracking systems, Oully monitors every stage of production and shipping. This visibility allows you to identify delays and resolve them quickly. 예를 들어, Oully uses real-time updates to track raw material shipments, ensuring timely arrivals. This proactive approach minimizes production downtime and keeps operations running smoothly.

Real-time data also helps Oully optimize delivery routes. By analyzing traffic patterns and weather conditions, Oully ensures faster and more reliable shipping. This efficiency reduces lead times and enhances customer satisfaction. When you adopt similar strategies, you can improve your supply chain performance and meet market demands more effectively.

울리: Achieving Cost Savings Through Automation

Automation has enabled Oully to achieve significant cost savings while maintaining high-quality standards. Automated systems handle repetitive tasks like filling, 라벨링, 그리고 포장, reducing labor costs. These systems also minimize errors, which lowers the cost of rework and waste.

예를 들어, Oully uses robotics to streamline its production lines. This technology increases output without requiring additional labor, making it a cost-effective solution. Automated quality checks further enhance efficiency by identifying defects early in the process. When you integrate automation into your operations, you can achieve similar cost savings and improve overall productivity.

울리: Enhancing Product Quality with Predictive Analytics

Predictive analytics has revolutionized how Oully ensures product quality. By analyzing production data, Oully identifies potential issues before they escalate. This approach reduces defects and enhances consistency.

증거 설명 | Impact on Product Quality |

|---|---|

Detects faulty bottles and equipment issues, leading to improved product quality and customer satisfaction. | |

Use of machine learning for predictive maintenance | Reduces unexpected downtime and production disruptions, enhancing overall product quality. |

Identification of improperly canned bottles and low filling lines | Decreases the number of defective bottles, ensuring consistent product quality. |

These innovations allow Oully to maintain high standards while meeting customer expectations. Predictive analytics ensures that every product aligns with your brand’s promise of quality.

Integrated manufacturing solutions revolutionize beauty supply chains by addressing key challenges and unlocking transformative benefits. These advancements improve transparency, 지속 가능성, and consumer trust through innovations like blockchain for traceability and AI-driven formulations.

Benefits include:

Enhanced operational efficiency

Better cost management

Stronger communication across supply chain segments

By adopting these solutions, you can streamline processes, reduce costs, and deliver consistent product quality. This approach positions your brand for long-term success in a competitive market while meeting evolving consumer expectations. Embrace integrated manufacturing to ensure your beauty brand thrives sustainably.

FAQ

What is integrated manufacturing in beauty supply chains?

Integrated manufacturing connects production, inventory, and logistics systems into one streamlined process. It uses technology like automation and predictive analytics to improve efficiency, reduce costs, and ensure consistent product quality.

How does automation benefit beauty manufacturing?

Automation speeds up production by handling repetitive tasks like filling and labeling. It reduces errors, lowers labor costs, and ensures consistent quality. You can scale operations easily while maintaining efficiency.

Can integrated manufacturing help with sustainability?

예! Integrated systems optimize resource use and reduce waste. Predictive analytics helps you plan production efficiently, minimizing environmental impact. Sustainable practices like waterless formulations and ethical sourcing become easier to implement.

How does predictive analytics improve demand forecasting?

Predictive analytics uses historical data and trends to forecast future demand. It helps you adjust inventory levels and production schedules proactively. This reduces stockouts and overproduction, ensuring you meet customer needs efficiently.

Is integrated manufacturing suitable for small beauty brands?

전적으로! Integrated solutions offer scalable options for businesses of all sizes. 낮은 MOQ (최소 주문 수량) options and automation tools make it easier for small brands to optimize operations and compete effectively.