يتطلب تصنيع مستحضرات التجميل الدقة والالتزام بخطوات صارمة لمراقبة الجودة. تضمن هذه التدابير بقاء المنتجات آمنة للمستهلكين مع الحفاظ على الأداء المتسق. تمتد مراقبة الجودة طوال دورة الحياة بأكملها لتطوير منتجات التجميل, من مصادر المواد الخام إلى التوزيع النهائي. تساعد بروتوكولات الاختبار الصارمة في تحديد المخاطر والقضاء عليها, حماية المستخدمين من المخاطر الصحية الناجمة عن التلوث أو التركيبة غير السليمة.

كما تعمل المعايير العالية في الإنتاج على حماية سمعة العلامة التجارية. أدوات مثل تراقب مخططات T² الخاصة بـ Hotelling معايير الجودة المتعددة مرة واحدة, تمكين الكشف المبكر عن الانحرافات وتحسين العمليات. هذا النهج يقلل من التكاليف ويعزز الكفاءة. من خلال إعطاء الأولوية للجودة, أنت تضمن الامتثال للوائح وتلبية توقعات العملاء.

اختيار المواد الخام واختبارها

البحث عن مكونات عالية الجودة لمستحضرات التجميل

أساس أي منتج تجميلي ناجح يكمن في جودة مكوناته. يجب عليك إعطاء الأولوية للمصادر من موردين موثوقين الذين يلتزمون بمعايير الصناعة. شهادات مثل ISO وGMP التأكد من أن المكونات تلبي معايير الجودة الصارمة. بالإضافة إلى ذلك, تضمن شهادات مثل USDA Organic وEcocert Natural استخدام المكونات الطبيعية والمستدامة.

يعد إنشاء بروتوكولات واضحة لتحديد مصادر المكونات وفحصها أمرًا ضروريًا. يتضمن ذلك التحقق من شهادات الموردين والحفاظ على وثائق دقيقة لإمكانية التتبع. من خلال الشراكة مع الموردين الجديرين بالثقة, يمكنك التأكد من أن عملية اختيار التركيبة والمكونات الخاصة بك تتوافق مع معايير السلامة والجودة.

اختبار الطهارة, أمان, والأداء

يلعب الاختبار دورًا حاسمًا في ضمان سلامة وفعالية مستحضرات التجميل الخاصة بك. الاختبارات الميكروبيولوجية يؤكد أن المكونات خالية من الكائنات الحية الدقيقة الضارة. يقوم اختبار الاستقرار بتقييم كيفية أداء المنتجات في ظل ظروف مختلفة, مثل درجة الحرارة والرطوبة. تساعدك هذه الاختبارات على تحديد المشكلات المحتملة مبكرًا, ضمان جودة متسقة.

بالإضافة إلى هؤلاء, الاختبارات الحسية تقيم الملمس, لون, ورائحة منتجاتك. تسجيل جميع نتائج الاختبارات والإبلاغ عنها وفقًا لـ أ نظام إدارة الجودة (نظام إدارة الجودة) يضمن المساءلة والامتثال. ويحدد نظام إدارة الجودة القوي أيضًا أهداف وعمليات الجودة, مساعدتك في الحفاظ على الاتساق طوال فترة الإنتاج.

الشراكة مع الموردين المعتمدين

يعمل التعاون مع الموردين المعتمدين على تقوية سلسلة التوريد الخاصة بك ويضمن جودة المكونات. الموردين المسجلين تحت تحديث قانون تنظيم مستحضرات التجميل 2022 (موكرا) تلبية متطلبات ادارة الاغذية والعقاقير, الحد من المخاطر المرتبطة بالمصادر التي لم يتم التحقق منها. تعمل عمليات التدقيق والشهادات المنتظمة مثل Fair Trade أو Leaping Bunny على التحقق من صحة الممارسات الأخلاقية والمستدامة.

عن طريق اختيار الموردين المعتمدين, فأنت لا تعمل فقط على تحسين جودة تركيبتك واختيار المكونات، بل أيضًا بناء الثقة مع عملائك. يضمن هذا النهج أن كل منتج تقوم بإنشائه يلبي أعلى معايير السلامة والأداء.

تخزين والتعامل مع المكونات

الحفاظ على سلامة المكونات من خلال التخزين المناسب

يضمن التخزين السليم سلامة مكونات مستحضرات التجميل طوال عملية الإنتاج. يجب عليك استخدام عبوات محكمة الغلق لحماية المواد من الرطوبة, تراب, والتلوث الميكروبي. قم بتسمية كل حاوية بوضوح بتفاصيل مثل الهوية, رقم الكثير, وتاريخ انتهاء الصلاحية. إن إبقاء المواد الخام بعيدًا عن الأرض وبعيدًا عن الملوثات المحتملة يزيد من جودتها.

تلعب الضوابط البيئية دورًا حيويًا في الحفاظ على استقرار المكونات. حاويات مقاومة للضوء تمنع التدهور في المواد الحساسة للضوء, بينما يتجنب تخزين الرطوبة المنخفضة المشكلات المتعلقة بالرطوبة. يعد التخزين المبرد ضروريًا للمنتجات الحساسة لدرجة الحرارة. يضمن تعقيم مناطق ومعدات التخزين بانتظام توفير بيئة نظيفة, تقليل خطر التلوث.

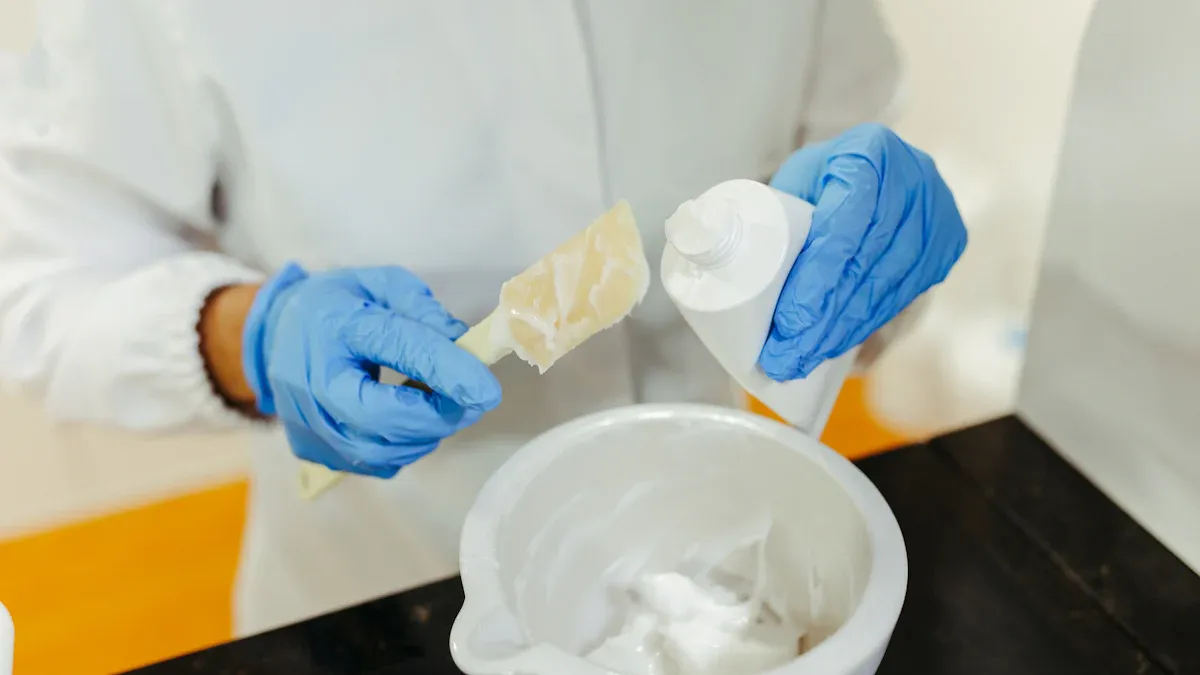

منع التلوث أثناء المناولة

يعد التعامل مع المكونات بعناية أمرًا ضروريًا لمنع التلوث أثناء عملية الإنتاج. تنفيذ بروتوكولات النظافة الصارمة للموظفين, بما في ذلك ارتداء القفازات, شبكات الشعر, والأقنعة. تدريب فريقك على اتباع أفضل الممارسات عند نقل المواد الخام أو قياسها.

الفحص الدوري للكائنات الحية الدقيقة الضارة, مثل البكتيريا أو العفن, يضمن بقاء المواد المخزنة آمنة للاستخدام. إنشاء قيم الحد الميكروبي لكل مكون بناءً على التطبيق المقصود. توفر طرق الاختبار المعتمدة نتائج متسقة, مساعدتك في الحفاظ على معايير عالية من السلامة والجودة.

تنفيذ أنظمة إدارة المخزون الفعالة

تعمل إدارة المخزون الفعالة على تبسيط عملية الإنتاج وتقليل النفايات. توفر الأنظمة الآلية تحديثات في الوقت الفعلي, منع الإفراط في التخزين ونفاذ المخزون. باستخدام أول في, أول خروج (يصرف أولاً) تضمن الطريقة استخدام المخزون الأقدم أولاً, التقليل من مخاطر المواد منتهية الصلاحية.

تسلط دراسات الحالة الضوء على فوائد الأتمتة. على سبيل المثال, قامت لوريال بتحسين دقة التنبؤ بالطلب و خفض مستويات المخزون بنسبة 15%, انتهى الادخار $10 مليون سنويا. قامت سيفورا بتحسين المخزون عبر شبكتها متعددة القنوات, تقليل عمليات الشطب بواسطة 20% وزيادة المبيعات بنسبة 11%. تعمل هذه الأنظمة على تحسين دقة الطلب وسرعة التنفيذ, تعزيز رضا العملاء وولائهم.

صياغة دقيقة وخلط

تحقيق الدقة في تطوير منتجات التجميل

تعد الدقة أمرًا ضروريًا في تطوير منتجات مستحضرات التجميل لضمان الجودة والأداء المتسقين. يجب عليك وضع إجراءات واضحة ل مراقبة توحيد الدفعة وسلامتها أثناء عملية الصياغة. تساعد هذه الإجراءات في الحفاظ على معايير عالية وتقليل الأخطاء.

المقياس الرئيسي الذي يجب تتبعه هو معدل نجاح مراقبة الجودة. يقيس هذا المعدل نسبة المنتجات التي تلبي معايير الجودة أثناء الاختبار. يمكنك حسابها باستخدام الصيغة:Quality Control Pass Rate (%) = (Number of Units Passed / Total Number of Units Tested) × 100

غالبًا ما تحقق الشركات الناجحة معدلات نجاح بين 95% و 98%, مما يعكس الكفاءة التشغيلية وسمعة العلامة التجارية القوية. إن السعي لتحقيق هذه الدقة يضمن تلبية منتجاتك لتوقعات العملاء والمتطلبات التنظيمية.

ضمان الخلط الموحد للاتساق

يعد الخلط الموحد أمرًا بالغ الأهمية لإنشاء منتجات تجميلية متسقة. تقنيات الخلط المتقدمة, مثل الخلاطات عالية القص وخلاطات المجانسة, تلعب دورا حيويا في تحقيق ذلك. تعمل هذه الأدوات على تحسين كفاءة الإنتاج وتضمن مستحلبات مستقرة, منع الانفصال في المنتجات مثل المستحضرات والكريمات.

يعمل المزج المتسق أيضًا على تحسين ملمس ومظهر تركيباتك. سلس, حتى الخلطات ضرورية لتقديم مستحضرات تجميل عالية الجودة. من خلال الاستثمار في عمليات الخلط الموثوقة, يمكنك التأكد من أن منتجاتك تحافظ على أدائها وجاذبيتها المقصودين.

الاستفادة من المعدات المتقدمة لتحقيق الدقة

استخدام المعدات المتقدمة يعزز الدقة في عملية الخلط. خلاطات كوكبية مزدوجة, على سبيل المثال, مثالية للتطبيقات عالية اللزوجة. تضمن شفراتها القوية مزجًا شاملاً, حتى مع المكونات الصعبة. أنظمة الخلط الذكية, متكاملة مع إنترنت الأشياء والذكاء الاصطناعي, خذ الدقة خطوة أخرى إلى الأمام. تقوم هذه الأنظمة بضبط المعلمات في الوقت الفعلي, ضمان نتائج متسقة عبر الدفعات.

المعدات المتقدمة أيضا تزيد من كفاءة الإنتاج. أنه يقلل من وقت الخلط, يقصر المهلة, ويضمن جودة المنتج موحدة. هذا التنوع يجعله مناسبًا لمجموعة واسعة من احتياجات تطوير منتجات التجميل, مما يساعدك على تحقيق نتائج استثنائية في كل مرة.

متطلبات | وصف |

|---|---|

الضوابط في العملية | يجب وضع إجراءات مكتوبة لمراقبة توحيد الدفعة وسلامتها. |

كفاية الخلط | يجب أن تضمن الإجراءات التجانس والتجانس في عملية الخلط. |

مواصفات الاختبار | يجب أن تكون المواصفات الصالحة مستمدة من متوسطات العملية السابقة وتقديرات التباين. |

من خلال الجمع بين تقنيات الصياغة الدقيقة, خلط موحد, والمعدات المتطورة, يمكنك رفع عملية تطوير منتجات مستحضرات التجميل الخاصة بك لتلبية أعلى المعايير.

جودة التغليف والسلامة

اختيار مواد التعبئة والتغليف المتينة والآمنة

يعد اختيار مواد التغليف المناسبة أمرًا حيويًا في إنتاج مستحضرات التجميل. يضمن التغليف المتين والآمن بقاء منتجاتك سليمة وفعالة طوال دورة حياتها. يجب عليك إعطاء الأولوية للمواد التي تلبي ثلاثة معايير رئيسية:

توافق المنتج: يمنع التفاعلات الكيميائية غير المرغوب فيها التي قد تؤثر على جودة مستحضرات التجميل الخاصة بك.

حماية المنتج: يحمي المنتجات من الهواء, رُطُوبَة, ضوء, والتغيرات في درجات الحرارة, الحفاظ على سلامتهم.

متانة: يقلل من خطر التسرب أو الكسر أثناء النقل والتخزين.

للتحقق من المتانة, يمكنك إجراء اختبارات مثل اختبارات السقوط, اختبارات الضغط, اختبارات الاهتزاز, الاختبارات الحرارية, واختبارات التعرض للأشعة فوق البنفسجية. تساعد هذه التقييمات على التأكد من أن عبواتك تلبي أعلى معايير الجودة والسلامة, حماية منتجاتك وسمعة علامتك التجارية.

اختبار توافق العبوة مع مستحضرات التجميل

يعد اختبار توافق التغليف أمرًا ضروريًا للتأكد من أن المواد الخاصة بك تعمل بشكل جيد مع تركيباتك. تقوم هذه العملية بتقييم كيفية تفاعل التغليف مع مستحضرات التجميل في ظل ظروف مختلفة. على سبيل المثال, اختبار التوافق العام يفحص تأثيرات درجة الحرارة, ضوء, والرطوبة على مدى عدة أسابيع أو أشهر. تقوم اختبارات التكسير الإجهادي بتقييم مقاومة المادة للتشقق, بينما تقوم اختبارات ما بعد المعالجة بتقييم تأثير العمليات الإضافية مثل الصدمة الحرارية.

وصف | الشروط/المدة | |

|---|---|---|

اختبار التوافق العام | يقيم كيفية تفاعل التغليف مع المنتج في بيئات مختلفة. | -20درجة مئوية إلى 50 درجة مئوية, التعرض للضوء, رطوبة, 4-8 أسابيع إلى عدة أشهر |

اختبار تكسير الإجهاد | تقييم مقاومة العبوة للتشقق تحت الضغط. | 23درجة مئوية إلى 50 درجة مئوية, 4-8 أسابيع أو أطول |

اختبار التوافق بعد المعالجة | يفحص تأثيرات العمليات الإضافية على التوافق. | 23درجة مئوية و 40 درجة مئوية, الصدمة الحرارية الدورية, 10 أيام |

معايير التقييم | يقيم المظهر, الخصائص الميكانيكية, فقدان الوزن, وأكثر. | بعد فترة الاختبار |

تضمن هذه الاختبارات أن تحافظ عبواتك على سلامتها وتدعم الجودة الشاملة والسلامة لمنتجاتك التجميلية.

تصميم عبوات مقاومة للتلاعب وسهلة الاستخدام

عبوة مقاومة للعبث يلعب دورا حاسما في وحدات تصنيع مستحضرات التجميل. إنه يحمي منتجاتك من الوصول غير المصرح به والتلوث, ضمان سلامة المستهلك. على سبيل المثال, ال 2019 حادثة العبث بالآيس كريم وسلط الضوء على أهمية التصاميم الواضحة للتلاعب في الحفاظ على الثقة ومنع الخسائر.

يمكنك تحسين عبواتك من خلال دمج ميزات مثل الأختام, تقليص العصابات, أو قبعات قابلة للكسر. لا تمنع هذه الإضافات التلاعب فحسب، بل تطمئن العملاء أيضًا بشأن سلامة منتجاتك. تساعدك التصميمات المقاومة للتلاعب أيضًا على الالتزام بمعايير السلامة القانونية, مواصلة تعزيز سمعة علامتك التجارية.

بالإضافة إلى ذلك, تعمل العبوة سهلة الاستخدام على تحسين تجربة المستهلك. تصميمات سهلة الفتح, وضع العلامات واضحة, والأشكال المريحة تجعل مستحضرات التجميل الخاصة بك أكثر جاذبية ويمكن الوصول إليها. من خلال التركيز على كل من السلامة وسهولة الاستخدام, يمكنك إنشاء عبوات تتوافق مع المعايير العالية لوحدة تصنيع مستحضرات التجميل الخاصة بك.

الامتثال التنظيمي والتوثيق

التنقل بين متطلبات إدارة الغذاء والدواء والمتطلبات التنظيمية العالمية

يعد فهم المعايير التنظيمية والالتزام بها أمرًا ضروريًا للحفاظ على سلامة وجودة مستحضرات التجميل الخاصة بك. لا تتطلب إدارة الغذاء والدواء موافقة مسبقة على مستحضرات التجميل, ولكن يجب عليك التأكد من امتثال منتجاتك لإرشاداتها. على سبيل المثال, يجب استبعاد الصيغ المكونات المحظورة مثل Bithionol وChloroform. يعد وضع العلامات الدقيقة نقطة تحكم حاسمة أخرى. إنه يبني ثقة المستهلك ويمنع مشكلات العلامات التجارية الخاطئة من خلال ذكر أسماء المنتجات بوضوح, الكميات الصافية, وقوائم المكونات.

عالميًا, ويصبح الامتثال التنظيمي أكثر تعقيدا. ال لائحة مستحضرات التجميل في الاتحاد الأوروبي 1223/2009 يفرض تقارير السلامة التفصيلية وتسجيل المنتج من خلال بوابة إشعارات منتجات التجميل (CPNP). بالإضافة إلى ذلك, تنظيم الإشراف والإدارة على مستحضرات التجميل في الصين (سيزار) يؤكد على مسؤوليات الشركات المصنعة في ضمان سلامة المنتج. يساعدك البقاء على اطلاع بهذه اللوائح على التغلب على تحديات الأسواق الدولية مع الحفاظ على معايير الإنتاج ومراقبة الجودة العالية.

الحفاظ على الوثائق الشاملة لعمليات التدقيق

يعد التوثيق الشامل حجر الزاوية في ممارسات التصنيع الجيدة. فهو يضمن الشفافية ويجهزك لعمليات التدقيق. يجب عليك الحفاظ سجلات مفصلة للمواد الخام, عمليات التصنيع, المنتجات النهائية, والتوزيع. على سبيل المثال, ويضمن توثيق التصرف في المواد المرفوضة والكميات المستخدمة في إنتاج الدُفعات إمكانية التتبع.

نوع الأدلة | وصف |

|---|---|

مواد خام | يجب الاحتفاظ بسجلات المواد الخام ومواد التعبئة والتغليف الأولية. |

تصنيع | توثيق الأنواع, الكثير, وكميات المواد المستخدمة في الإنتاج. |

المنتجات النهائية | تشمل أخذ العينات, الضوابط المخبرية, ونتائج الاختبار. |

توزيع | تسجيل الشحنة الأولية بين الولايات والمرسل إليهم. |

لا تدعم هذه السجلات الامتثال التنظيمي فحسب، بل تعمل أيضًا على تعزيز قدرتك على تحديد ومعالجة نقاط التحكم الحرجة في الإنتاج.

البقاء على اطلاع دائم بمعايير الصناعة

صناعة مستحضرات التجميل تتطور بسرعة, مع اللوائح والمعايير الجديدة التي تظهر بانتظام. يضمن البقاء على اطلاع دائم أن منتجاتك تلبي أحدث المتطلبات. على سبيل المثال, قام الاتحاد الأوروبي مؤخرًا بتوسيع قواعد وضع العلامات على العطور المسببة للحساسية, زيادة الشفافية وسلامة المستهلك. بصورة مماثلة, الصين 2023 قدمت اللوائح مبادئ توجيهية أكثر صرامة لأخذ عينات مستحضرات التجميل والعمليات عبر الإنترنت.

اعتماد الآيزو 22716 يعد المعيار طريقة أخرى للتوافق مع أفضل الممارسات العالمية. يركز هذا المعيار على ممارسات التصنيع الجيدة, مع التركيز على مراقبة الجودة والسلامة في جميع أنحاء الإنتاج. من خلال البقاء على اطلاع واستباقية, يمكنك التكيف مع التغييرات في المعايير التنظيمية والحفاظ على قدرتك التنافسية.

اختبار المنتج النهائي والتفتيش

إجراء الاختبارات الميكروبيولوجية والثباتية

يضمن الاختبار الميكروبيولوجي واختبار الثبات أن تظل مستحضرات التجميل الخاصة بك آمنة وفعالة طوال فترة صلاحيتها. تقوم الاختبارات الميكروبيولوجية بتقييم وجود الكائنات الحية الدقيقة الضارة, بينما يقوم اختبار الثبات بمراقبة التغيرات في اللون, رائحة, والملمس في ظل ظروف مختلفة. تساعدك هذه الاختبارات على تحديد المخاطر المحتملة مبكرًا والحفاظ على جودة المنتج.

غالبًا ما تتضمن بروتوكولات اختبار الثبات تقييمات ميكروبيولوجية للتحقق من فعالية المواد الحافظة. يجب عليك إجراء الاختبارات في نقاط زمنية مختلفة, مع الأخذ في الاعتبار العوامل البيئية مثل درجة الحرارة والرطوبة. على سبيل المثال:

الدراسة/المبادئ التوجيهية | النتائج الرئيسية |

|---|---|

دليل إلى OTC & اختبار ثبات مستحضرات التجميل | يسلط الضوء على أهمية الاختبارات الميكروبيولوجية في بروتوكولات الاستقرار. |

الاستقرار الميكروبيولوجي لمستحضرات التجميل | يؤكد على مكافحة التلوث الميكروبي واستخدام اختبارات التحدي. |

ملاحظات SCCP التوجيهية | يجب أن تكون الكائنات الحية الدقيقة المسببة للأمراض غائبة في مستحضرات التجميل للأطفال. |

لائحة المفوضية الأوروبية رقم. 1993/2009 | ولايات تقييم الاستقرار الميكروبيولوجي مع مرور الوقت. |

تضمن هذه الممارسات تلبية منتجاتك لمعايير اختبار السلامة وبقائها مستقرة خلال دورة حياتها.

الفحص البصري للعيوب والتناقضات

تلعب عمليات الفحص البصري دورًا حاسمًا في اكتشاف العيوب والتناقضات في مستحضرات التجميل. يمكنك تحديد مشكلات مثل تلف العبوة, عدم تطابق الألوان, أو القوام غير المستوي من خلال هذه العملية. تساعدك تقييمات الكشف على قياس فعالية عمليات الفحص البصري:

تصنيف الكشف | وصف |

|---|---|

1 | سيتم الكشف عنها دائمًا |

10 | لا توجد فرصة للكشف |

2-9 | يختلف على أساس التعقيد |

عادة ما يتم تحقيق عمليات التفتيش البصرية تصنيفات الكشف بين 6 و 10 للعيوب المعقدة. وتتراوح طرق القياس من 2 ل 6, بينما تسجل الأنظمة المقاومة للخطأ ما بين 1 و 4. تضمن هذه التصنيفات تلبية منتجاتك لتوقعات العملاء أثناء عمليات فحص المنتج النهائية.

اختبار الدفعة لضمان الجودة

يتحقق اختبار الدُفعات من اتساق وسلامة كل دفعة إنتاج. يجب عليك تنفيذ منهجيات مثل الاختبار أثناء العملية, التقييم الحسي, واختبار الاستقرار المتسارع لمراقبة المعلمات الرئيسية. على سبيل المثال:

المنهجية | وصف |

|---|---|

الاستقرار مع مرور الوقت | الشاشات تغيرات في اللون, رائحة, أو الملمس طوال مدة الصلاحية. |

اختبار في العملية | يتحقق بانتظام من اللزوجة, PH, والمستويات الميكروبية أثناء الإنتاج. |

مراقبة العمليات الإحصائية | يتتبع المعلمات الرئيسية ويطلق الإجراءات التصحيحية للانحرافات. |

العينات المرجعية | يحتفظ بعينات من كل دفعة لإجراء مقارنات مستقبلية. |

يحاكي استخدام المنتج لتقييم فعالية المواد الحافظة. |

تضمن هذه الطرق تلبية منتجاتك لمعايير القبول المحددة. إذا تجاوزت النتائج الحدود, الإجراءات التصحيحية تمنع التلوث وتحافظ على الجودة. يعمل اختبار الدُفعات على تقوية عملية ضمان الجودة لديك, ضمان مستحضرات تجميل آمنة ومتسقة لعملائك.

التحسين المستمر وردود الفعل

الاستفادة من ملاحظات العملاء من أجل التحسين

تعد تعليقات العملاء بمثابة أداة قوية لتحسين منتجات التجميل. يساعدك الاستماع إلى جمهورك على تحديد مجالات التحسين ومواءمة عروضك مع تفضيلاتهم. منصات التواصل الاجتماعي, استطلاعات ما بعد الشراء, وتوفر مراجعات المنتجات رؤى قيمة حول احتياجات العملاء. من خلال تحليل هذه البيانات, يمكنك تعزيز الصيغ الخاصة بك, التعبئة والتغليف, وتجربة المنتج الشاملة.

على سبيل المثال, نجحت العلامات التجارية مثل Sephora وFenty Beauty في الاستفادة من تعليقات العملاء لتحسين منتجاتها. سيفورا قامت بتوسيع نطاق الظل لخط Cream Lip Stain بعد تحليل المراجعات, بينما استجابت شركة Fenty Beauty للانتقادات المتعلقة بالشمولية من خلال تقديم المزيد من الألوان. لم تؤدي هذه الإجراءات إلى تحسين جودة المنتج فحسب، بل عززت أيضًا ولاء العملاء.

ماركة | دليل على تأثير ملاحظات العملاء | وصف |

|---|---|---|

مستحضرات التجميل الخصبة | استخدام أدوات الاستماع عبر وسائل التواصل الاجتماعي لتحديد الاتجاهات والتفضيلات. | تطوير خطوط إنتاج جديدة تتوافق مع قيم العملاء. |

سيفورا | تحليل مراجعات العملاء لتحسين عروض المنتجات. | تم توسيع نطاق الظل لخط Cream Lip Stain بناءً على تفضيلات العملاء. |

فنت الجمال | تم الرد على الانتقادات المتعلقة بتوفر الظل من خلال توسيع نطاقه. | تعزيز الالتزام بالشمولية والتنوع بعد التعليقات الأولية على الإطلاق. |

أكثر لمعانًا | دمج المحتوى الذي ينشئه المستخدم في استراتيجيات التسويق. | بناء علامة تجارية تركز على المجتمع حول مفهوم "إضفاء الطابع الديمقراطي على الجمال". |

إستي لودر | تم تنفيذ استطلاعات ما بعد الشراء لجمع رؤى للتحسينات المستقبلية. | تعزيز الحوار المستمر مع العملاء لتعزيز الرضا وتطوير المنتج. |

من خلال دمج ملاحظات العملاء في العملية الخاصة بك, يمكنك تحقيق التحسين المستمر وتقديم المنتجات التي تلقى صدى لدى جمهورك.

إجراء عمليات تدقيق منتظمة للجودة

تضمن عمليات تدقيق الجودة أن تظل عملية التصنيع الخاصة بك فعالة ومتوافقة مع معايير الصناعة. تساعدك عمليات التدقيق هذه على تحديد نقاط الضعف وتنفيذ الإجراءات التصحيحية للحفاظ على إنتاج عالي الجودة. التقييمات المنتظمة للمرافق الخاصة بك, معدات, والإجراءات تمنع الأخطاء وتحسن الاتساق.

يجب عليك وضع جدول زمني لعمليات التدقيق الداخلي وتوثيق النتائج بدقة. التركيز على مجالات مثل مصادر المكونات, دقة الصياغة, وسلامة التعبئة والتغليف. توفر عمليات التدقيق أيضًا فرصًا لتقييم الامتثال للمتطلبات التنظيمية, ضمان تلبية منتجاتك لمعايير السلامة. عن طريق إجراء عمليات تدقيق منتظمة, أنت تعزز التزامك بالتحسين المستمر وبناء الثقة مع عملائك.

الاستثمار في تدريب الموظفين وتطويرهم

يلعب فريقك دورًا حاسمًا في الحفاظ على الجودة طوال عملية التصنيع. يضمن الاستثمار في تدريب الموظفين فهم موظفيك لأفضل الممارسات وبقائهم على اطلاع دائم بتطورات الصناعة. يجب أن تغطي برامج التدريب موضوعات مثل بروتوكولات النظافة, تشغيل المعدات, والامتثال التنظيمي.

مبادرات تنموية, مثل ورش العمل والشهادات, تعزيز مهارات الموظفين وتعزيز ثقافة التميز. على سبيل المثال, التدريب على تقنيات الخلط المتقدمة يمكن أن يحسن دقة الصياغة, بينما يمكن للجلسات الخاصة بأنظمة إدارة المخزون تبسيط العمليات. يساهم الفريق المدرب جيدًا في التحسين المستمر من خلال تقليل الأخطاء وزيادة الكفاءة.

تشجيع ردود الفعل من الموظفين لتحديد مجالات النمو. يمكن أن تساعدك رؤاهم في تحسين العمليات والتكيف مع متطلبات الصناعة المتغيرة. من خلال إعطاء الأولوية للتدريب والتطوير, أنت تقوم بتمكين فريقك من الالتزام بالمعايير العالية ودفع الابتكار.

يبدأ إتقان تصنيع الماكياج بتنفيذ سبع خطوات أساسية لمراقبة الجودة. وتشمل هذه اختيار المواد الخام عالية الجودة, تخزين والتعامل مع المكونات بشكل صحيح, ضمان صياغة دقيقة, اختبار سلامة التعبئة والتغليف, الامتثال للوائح, فحص المنتجات النهائية, وتعزيز التحسين المستمر. تلعب كل خطوة دورًا حيويًا في إنشاء مستحضرات تجميل آمنة ومتسقة.

إن تحديد أولويات مراقبة الجودة يحمي سمعة علامتك التجارية ويبني ثقة العملاء. فهو يضمن أن منتجاتك تلبي معايير السلامة وتعمل بشكل موثوق.

يؤدي اعتماد هذه الممارسات إلى تعزيز عملية التصنيع الخاصة بك ويساعدك على تقديم مستحضرات تجميل استثنائية تتجاوز التوقعات.

التعليمات

ما هي الخطوة الأكثر أهمية في تصنيع المكياج؟?

كل خطوة مهمة, ولكن اختيار المواد الخام يبرز. تضمن المكونات عالية الجودة أن منتجك يلبي معايير السلامة والأداء. ويضمن اختبار النقاء والشراكة مع الموردين المعتمدين الحصول على نتائج متسقة.

كيف يمكنك التأكد من سلامة التعبئة والتغليف لمستحضرات التجميل؟?

يجب عليك إجراء اختبارات التوافق للتأكد من أن مواد التعبئة والتغليف تعمل بشكل جيد مع منتجك. تقوم هذه الاختبارات بتقييم المتانة, مقاومة العوامل البيئية, والتفاعلات الكيميائية, ضمان بقاء مستحضرات التجميل الخاصة بك آمنة وفعالة.

لماذا يعتبر اختبار الدُفعات ضروريًا في مراقبة الجودة?

يتحقق اختبار الدُفعات من اتساق وسلامة كل دفعة إنتاج. يساعد على تحديد العيوب في وقت مبكر, ضمان أن منتجك يلبي معايير الجودة المعمول بها. تحمي هذه الخطوة سمعة علامتك التجارية وتبني ثقة العملاء.

كيف تعمل تعليقات العملاء على تحسين منتجات مستحضرات التجميل?

ملاحظات العملاء تسلط الضوء على مجالات التحسين. من خلال تحليل المراجعات والاستطلاعات, يمكنك تحسين الصيغ, تعزيز التعبئة والتغليف, ومواءمة منتجك مع تفضيلات المستهلك. هذه العملية تعزز الولاء وتضمن التحسين المستمر.

ما هو الدور الذي يلعبه تدريب الموظفين في مراقبة الجودة؟?

يحافظ الموظفون المدربون جيدًا على المعايير العالية طوال عملية التصنيع. تعمل برامج التدريب على تحسين المهارات في مجالات مثل النظافة, تشغيل المعدات, والامتثال التنظيمي. يضمن الفريق ذو المعرفة أن منتجك يلبي توقعات الجودة باستمرار.