Thriving in cosmetic manufacturing requires more than producing cosmetics; it demands strategic planning and execution. You must embrace innovation, ensure consistent quality, and optimize efficiency to stand out in this competitive industry. 예를 들어, Shanghai BeautyCo improved its performance from 38 에게 88 전철기 in eight months by implementing changes like better online marketing and storage management. This success highlights how innovation and efficiency directly impact your ability to compete. Meeting consumer expectations while adhering to regulatory standards transforms your products into trusted solutions that customers value.

Understanding the Market and Consumer Needs

Conducting Market Research

Market research is the foundation of a successful cosmetics manufacturing process. It helps you understand what consumers want and how to meet their expectations. Using proven methods like consumer surveys, 포커스 그룹, and product testing can provide valuable insights. 예를 들어:

Method | 설명 |

|---|---|

Consumer Surveys | Collect data on preferences, purchasing habits, and satisfaction. |

포커스 그룹 | Discuss perceptions and motivations with small groups. |

Product Testing | Evaluate product performance through consumer trials. |

Market Segmentation Studies | Identify key consumer groups for targeted marketing. |

Concept Testing | Test new product ideas to refine offerings before launch. |

By applying these methods, you can identify gaps in the market and create products that resonate with your audience.

Identifying Emerging Trends

Staying ahead of trends is essential in the global cosmetics manufacturing industry. Innovations like AI and AR technologies are transforming the cosmetics manufacturing process by offering personalized beauty experiences. 또한, biotech advancements are driving sustainable solutions. Consider these key trends:

Smart beauty devices are growing at an annual rate of 18.8%.

E-commerce now accounts for ~ 위에 20% of total beauty sales, a 12% yearly growth rate.

Sales in the beauty industry are projected to reach $144.2 10 억으로 2028.

By monitoring these trends, you can adapt your cosmetics manufacturing process to meet evolving consumer demands.

Understanding Consumer Preferences and Pain Points

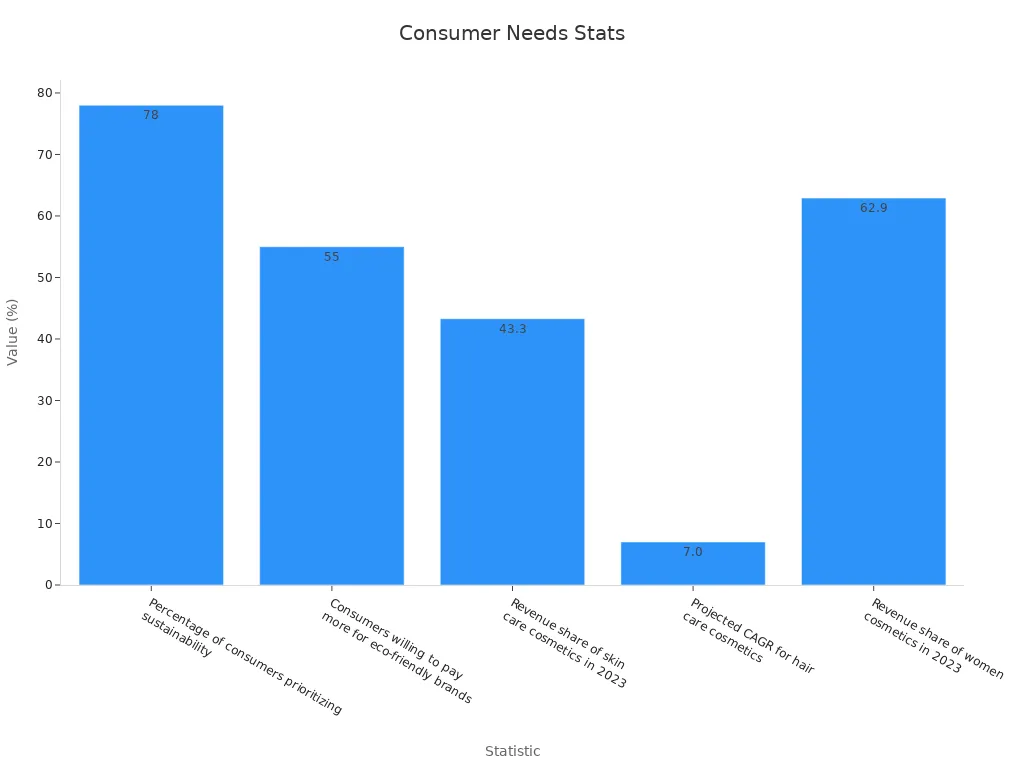

Understanding what your customers value is critical. Many consumers prioritize sustainability, 윤리적 소싱, 그리고 천연성분. Others seek luxury and exclusivity. Here are some key insights:

Brand loyalty influences purchasing decisions.

Price sensitivity affects consumer choices.

High-quality products remain a top priority.

또한, conscious consumers prefer recyclable packaging and eco-friendly practices. Addressing these preferences can help you build trust and loyalty among your target audience.

Leveraging Professional Cosmetic Manufacturing Services

Benefits of Contract Manufacturing

Outsourcing your cosmetics manufacturing to professional cosmetic manufacturing services offers several advantages. These manufacturers bring expertise and advanced technology to the table, ensuring high-quality products. They also help you save costs by eliminating the need for expensive equipment and reducing staffing requirements. 또한, they can respond quickly to changes in demand, helping you stay competitive in a fast-paced market. 아웃소싱 생산으로, you can focus on core activities like product development and marketing, which are crucial for growing your brand.

Key benefits include:

Access to expertise and cutting-edge technology.

Significant cost savings on equipment and labor.

Faster response times to market demands.

More time to concentrate on innovation and branding.

Choosing the Right Manufacturing Partner

Selecting the right partner for your cosmetics manufacturing is critical. A reliable partner ensures smooth operations and consistent product quality. Evaluate potential partners using key performance indicators (KPI) to make an informed decision.

KPI | 설명 | Ideal Value |

|---|---|---|

총 이익률 | Understanding the profitability of products. | 60-80% |

생산 효율성 | Minimizing waste and maximizing output. | 위에 85% |

품질관리 합격률 | Maintaining product integrity and brand reputation. | 95% 또는 더 높습니다 |

Order Fulfillment Cycle Time | Enhancing customer satisfaction and loyalty. | 2-3 날 |

These metrics help you identify a partner who aligns with your business goals and ensures reliable skin care manufacturing.

비용 효율성 및 확장성

Professional cosmetic manufacturing services provide cost-effective solutions that support scalability. By outsourcing, you can reduce operational expenses like facility rent, utilities, and maintenance. 예를 들어:

Facility rent typically accounts for 15-25% of total expenses. Negotiating long-term leases can lower costs.

Energy-efficient equipment reduces utility bills and supports sustainability goals.

Regular maintenance prevents unexpected repair costs and extends equipment lifespan.

Integrating cosmetics manufacturing software further enhances cost control. This software provides real-time visibility across operations, streamlining processes and reducing inefficiencies. It also supports scalability, enabling you to meet growing demand without compromising quality.

제품 개발의 맞춤화 및 혁신

Developing Unique Formulations

Creating unique formulations is essential for standing out in the cosmetics industry. You can achieve this by experimenting with innovative combinations of ingredients. 예를 들어, Shiseido uses artificial intelligence (일체 포함) to analyze over half a million data points, including ingredient properties and sensory experiences. This approach allows for precise and efficient product development.

Here’s how AI benefits cosmetics manufacturing:

그것 enhances consumer experience by enabling virtual product exploration.

It provides analytics on customer preferences, helping you develop new variations.

It improves operational efficiency, allowing quick adaptation to market demands.

또한, successful formulation experiments demonstrate the importance of precise ratios. 예를 들어:

Formulation Components | Ratios | Success Rate (Preservation) |

|---|---|---|

Sodium coco PG-dimonium chloride phosphate, Ricinoleic acid, Raspberry ketone | 1:6.3:6.3 | |

Sodium coco PG-dimonium chloride phosphate, Palmitoleic acid, Sorbitan caprylate | 1:12.5:37.5 | Preserved for 28 날 |

By leveraging advanced tools and precise formulation techniques, you can create custom personal care products that meet consumer expectations.

Incorporating Sustainable and Natural Ingredients

Consumers increasingly prefer cosmetics made with sustainable and natural ingredients. This shift reflects growing awareness of environmental and health concerns. Products with plant-based, 잔인하지 않은, and non-toxic ingredients are in high demand. Certifications like USDA Organic and COSMOS also boost consumer confidence.

증거 설명 | 주요 통찰력 |

|---|---|

Consumers are increasingly aware of product ingredients and prefer natural options. | Demand for plant-based, 잔인하지 않은, and non-toxic products is rising, especially in cosmetics. |

Clean beauty certifications are gaining traction. | Certifications like USDA Organic and COSMOS enhance consumer confidence in natural products. |

There is a shift towards eco-friendly packaging. | Manufacturers are adopting biodegradable materials and refillable options to reduce waste. |

Incorporating these practices into your product development and manufacturing process not only meets consumer demands but also strengthens your brand’s reputation.

Staying Ahead with Technological Advancements

Technological advancements are revolutionizing cosmetics manufacturing. AI plays a significant role in personalized product development, offering tailored recommendations for consumers. 예를 들어, the cosmetics sector in Spain experienced an 11.3% growth in 2022, with exports reaching 6.515 billion euros. This growth highlights the impact of innovation on the industry.

By adopting cutting-edge technologies, you can streamline operations and enhance product quality. AI tools, 예를 들어, allow you to analyze market trends and consumer preferences, ensuring your products remain relevant. Staying ahead with technology ensures your brand remains competitive in a rapidly evolving market.

Ensuring Quality Control and Compliance

Adhering to Regulatory Standards

Regulatory standards ensure the safety and reliability of cosmetics. You must comply with guidelines like FDA regulations, EU 화장품 규정, ISO 표준. These frameworks oversee product labeling, 성분 안전, 및 제조 관행. 예를 들어:

Regulation/Guideline | 설명 |

|---|---|

FDA Regulations | Oversees safety and labeling of cosmetic products in the U.S. |

EU 화장품 규정 | Sets high human safety standards for cosmetics in the European Union. |

ISO Guidelines | Provides global guidelines for Good Manufacturing Practices (GMP) and organic product standards. |

Mandatory registration and ingredient disclosure further strengthen compliance. You must also substantiate product safety through testing and monitoring adverse events. These steps protect consumers and prevent violations like warning letters or product seizures.

Implementing Rigorous Testing Protocols

Testing protocols are vital for maintaining product quality and safety. You should test raw materials, in-process samples, and finished products to ensure compliance with specifications. 예를 들어:

Testing Type | 목적 |

|---|---|

Raw Materials Testing | Verifies identity and compliance with physical and chemical properties. |

In-Process Samples | Ensures that products meet specifications during manufacturing. |

Finished Products Testing | Confirms that final products are free from contaminants and meet safety standards. |

Periodic testing also validates product claims and performance. Experimental studies measure objective factors like skin hydration or pigmentation changes, while consumer perception tests provide subjective feedback. These methods ensure your cosmetics manufacturing process delivers safe and effective products.

Maintaining Consistency Across Batches

Consistency across batches builds trust in your brand. You can achieve this by standardizing formulations, automating manufacturing systems, and training employees to follow strict protocols. 예를 들어:

Quality Control Measure | 설명 |

|---|---|

Standardized Formulations | Accurate measurement and mixing of ingredients to maintain consistency across batches. |

Batch Testing and Sampling | Testing samples from each batch for quality, performance, and safety to identify issues early. |

Automated Manufacturing Systems | Use of automation to control processes and reduce human error, 일관된 제품 품질 보장. |

Ingredient sourcing and supplier control also play a key role. Reliable suppliers ensure high-quality raw materials, while audits and communication prevent variability. Packaging and storage consistency further enhance product reliability. By prioritizing these measures, you can streamline the manufacturing process of cosmetics and deliver uniform products every time.

Optimizing Packaging and Presentation

Designing Eye-Catching Packaging

Packaging plays a pivotal role in attracting consumers and influencing their purchasing decisions. The design of packaging, including colors and shapes, creates a memorable first impression. It acts as a silent initiator of the buyer-product relationship, capturing attention and fostering emotional engagement. 예를 들어, vibrant colors and sleek shapes often appeal to younger audiences, while minimalist designs resonate with eco-conscious consumers.

Consumer feedback highlights the importance of aesthetics in cosmetics packaging. Surveys reveal that visually appealing designs enhance emotional connections and drive sales. Competitor analysis also shows how innovative packaging can set brands apart in the crowded cosmetics market.

증거 유형 | 설명 |

|---|---|

소비자 피드백 | Insights from surveys and focus groups regarding packaging preferences. |

Competitor Analysis | Examination of how competitors innovate in packaging within the cosmetics sector. |

Aesthetics and Branding | Analysis of how design elements like color and shape attract specific consumer demographics. |

디자인에 중점을 두어, you can create packaging that not only stands out but also aligns with consumer expectations.

Prioritizing Functionality and Sustainability

Modern consumers demand packaging that balances functionality with sustainability. Refillable systems, modular designs, and minimalist approaches are gaining popularity. Refillable packaging encourages reuse, 폐기물 감소. Modular designs allow parts to be replaced, extending the lifecycle of packaging. Minimalist packaging eliminates unnecessary components, aligning with eco-friendly preferences.

Sustainable materials like glass, paper, and bioplastics offer unique benefits. Glass is luxurious and recyclable but heavier, increasing transport emissions. Paper is biodegradable and compostable but less protective. Bioplastics reduce carbon emissions but require specific conditions for degradation. By integrating these materials, you can create packaging that meets both environmental and functional needs.

Sustainable packaging design also involves minimizing waste and using recyclable materials. 예를 들어, designing for easy disassembly facilitates recycling, reducing the environmental impact of cosmetics manufacturing.

Aligning Packaging with Brand Identity

Packaging serves as the first physical interaction between your brand and the consumer. It acts as a mini billboard, reflecting your brand’s essence and building recognition. Luxury cosmetic packaging, 예를 들어, creates a timeless experience, enhancing brand identity and fostering trust.

Research shows that cohesive packaging strengthens customer engagement. Aligning packaging with your brand narrative ensures consistency across all touchpoints. This approach not only makes a lasting impression but also reinforces your brand’s values. 예를 들어, eco-friendly packaging for cosmetics aligns with brands promoting sustainability, 대담하면서도, vibrant designs suit brands targeting younger demographics.

By prioritizing alignment with your brand identity, you can create packaging that resonates with your audience and enhances your market presence.

Streamlining Production Processes

Implementing Lean Manufacturing Practices

Lean manufacturing practices help you eliminate inefficiencies and improve the cosmetics manufacturing process. By focusing on reducing waste and optimizing workflows, you can enhance productivity and minimize costs. Key metrics like cycle time and first pass yield provide valuable insights into your operations. 예를 들어:

메트릭 | 설명 |

|---|---|

Cycle Time | Average time taken to complete a customer order. |

First Pass Yield | Number of non-defective products built the first time without rework. |

Capacity Utilization | Measures the percentage of a plant’s production capacity that is currently in use. |

Machine Downtime Rate | Duration for which equipment is unavailable for production. |

Overtime Rate | Measures the extra hours employees work beyond their scheduled hours. |

By tracking these metrics, you can identify bottlenecks and implement solutions to streamline the manufacturing process of cosmetics. 예를 들어, reducing machine downtime and improving first pass yield ensures consistent product quality while lowering operational costs.

Investing in Automation and Technology

Automation and technology are transforming the cosmetics manufacturing process. AI-powered systems enhance efficiency by reducing human error and speeding up production. 예를 들어, an AI-powered lipstick inspection system improved accuracy and consistency in quality control. It also alleviated production bottlenecks and enhanced traceability throughout the production process.

또한, 98% of manufacturers have already started their digital transformation journey. This shift focuses on cost optimization, 운영 효율성, and product innovation. Generative AI, 예를 들어, offers an average return on investment (ROI) of 3.7x, making it a valuable tool for cosmetics manufacturing. By adopting automation and data analytics, you can improve product quality and respond to consumer demands more effectively.

Reducing Waste and Improving Efficiency

The cosmetics industry generates over 120 billion units of plastic packaging waste annually, with only 9% being recycled. Transitioning to sustainable practices can significantly reduce this environmental impact. 예를 들어, Pai Skincare reduced its plastic use by 35% in a year by adopting alternative materials.

Real-time visibility into the production lifecycle also helps you identify contamination risks and improve efficiency. Enhanced inventory tracking mitigates cross-contamination by monitoring temperature and storage conditions. Granular data capture enables quick identification of contamination sources, allowing for faster corrective actions. These measures not only reduce waste but also ensure a more efficient cosmetics manufacturing process.

Effective cosmetic manufacturing requires a strategic approach. You must understand the market, leverage professional services, and prioritize quality and innovation. These strategies help you create cosmetics that meet consumer expectations and stand out in a competitive industry. By focusing on customization, 지속 가능성, and advanced technology, you can deliver products that resonate with your audience. Consistent quality and efficient processes further strengthen your brand’s reputation. Adopting these practices ensures your cosmetics remain relevant and trusted. Start implementing these strategies today to stay ahead in the ever-evolving cosmetics market.

FAQ

What is the most important factor in cosmetic manufacturing?

일관성이 핵심이다. You must ensure uniformity in formulations, 품질, and packaging across all batches. This builds trust with your customers and strengthens your brand reputation.

How can I make my cosmetic products stand out?

Focus on customization and innovation. Develop unique formulations, use sustainable ingredients, and adopt eye-catching packaging that aligns with your brand identity. These strategies help you differentiate your products in a competitive market.

Why is sustainability important in cosmetic manufacturing?

Sustainability meets consumer demand for eco-friendly products and reduces environmental impact. Using recyclable packaging, 천연 성분, and energy-efficient processes enhances your brand’s appeal and supports long-term growth.

How do I choose the right manufacturing partner?

Evaluate potential partners based on their certifications, production capabilities, 및 품질 관리 조치. Look for a partner like Oully, which offers expertise, scalability, and compliance with industry standards.

What role does technology play in cosmetic manufacturing?

Technology improves efficiency and quality. Automation reduces errors, while AI helps analyze trends and develop innovative products. Investing in technology keeps your operations competitive and responsive to market demands.