Balancing quality and cost is essential for any private label cosmetic brand aiming for long-term success. Consumers today expect high standards, and their purchasing decisions often reflect this. 例えば:

以上 64% prefer products in sustainable packaging, even if they cost more.

This balance quality directly impacts your brand’s reputation and profitability. High-quality cosmetics build trust, while effective cost management ensures sustainable growth. When launching your brand, maintaining quality assurance without overspending becomes a strategic priority. By aligning balance quality and compliance with a strong cost strategy, you set the foundation for a successful product launch and lasting customer loyalty.

Understanding the Cost-Quality Tradeoff

The Relationship Between Cost and Quality in Private Label Cosmetics

In private label cosmetics, cost and quality often go hand in hand. High-quality products typically require premium ingredients, advanced formulations, and rigorous testing, all of which increase production costs. 例えば, natural ingredients like organic oils or plant extracts cost more than synthetic alternatives due to their sourcing and processing requirements. Custom formulations also add to expenses, as they involve extensive research and development to ensure safety and stability.

Factor | 説明 |

|---|---|

Quality of Ingredients | Premium ingredients, such as organic or rare components, significantly increase production costs. |

Natural vs. Synthetic Ingredients | Natural ingredients are generally more expensive due to sourcing and processing requirements. |

カスタム定式化 | Tailored formulations incur higher R&D costs due to extensive testing for stability and safety. |

r&D Expenses | Developing unique products from scratch involves significant costs for testing and regulatory compliance. |

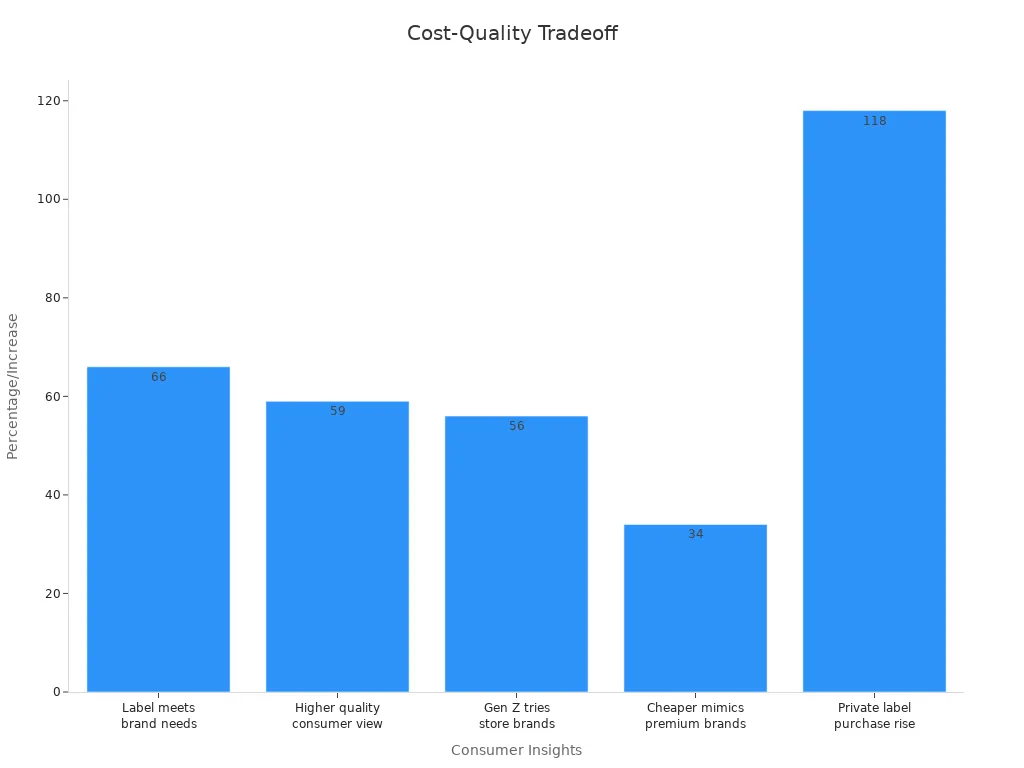

Despite these costs, maintaining quality is essential for building a strong brand strategy. Consumers increasingly expect private label cosmetics to match or exceed the standards of established brands. According to recent data, 59% of consumers believe private label products now offer better quality, while 66% feel they meet their needs as effectively as branded options.

Common Misconceptions About Balancing Quality and Cost

Many believe that reducing costs always leads to lower quality. しかし, this isn’t always true. Strategic decisions, such as sourcing ingredients in bulk or partnering with experienced manufacturers like Oully, can help you lower costs without compromising quality. Another misconception is that premium packaging guarantees better products. While packaging plays a role in consumer perception, the actual formulation and performance of the product matter more.

さらに, some assume that private label cosmetics can’t compete with established brands. まだ, the growing popularity of private labels proves otherwise. From 2022 に 2024, there has been a 118% increase in consumers willing to purchase private label beauty products, highlighting their trust in quality and affordability.

Why Private Label Cosmetic Brands Must Prioritize Balance

Balancing quality and cost is not just a strategy—it’s a necessity for private label cosmetic brands. Focusing solely on cost can harm your brand’s reputation, while prioritizing quality without cost control can hurt profitability and growth. Striking the right balance ensures you deliver products that meet customer expectations while maintaining financial sustainability.

Private label cosmetics offer unique advantages. They allow you to customize products to meet specific consumer needs, enhancing their appeal. By balancing quality and cost, you can achieve profitability and control over your brand’s success. This balance also supports the power of effective marketing, as satisfied customers often become loyal advocates for your products.

Key Factors Influencing Quality and Cost

製品の定式化と成分の選択

Product formulation plays a critical role in determining both the quality and cost of private label cosmetics. The ingredients you choose directly impact the product’s performance, safety, and appeal to consumers. High-quality ingredients, such as organic oils or plant-based extracts, often come with a higher price tag. しかし, they deliver better results and align with consumer preferences for natural and effective products.

When developing winning formulations, you must evaluate each ingredient for its functionality, safety, and compliance with regulations. 例えば:

Ingredients like hyaluronic acid or retinol enhance skincare benefits but require careful testing to ensure stability and effectiveness.

Poorly constructed formulations can negate the benefits of even the best ingredients, leading to dissatisfied customers.

Understanding raw material specifications is equally important. Variations in ingredient quality can affect the final product’s performance and your brand’s reputation. By working with experienced manufacturers, you can ensure consistent quality while optimizing costs. Manufacturers often use tools like Statistical Process Control (SPC) and Quality by Design (QbD) principles to maintain high standards during production. These methods help foresee potential issues and address them before mass production begins.

Raw Material Sourcing and Supplier Partnerships

Sourcing raw materials is another key factor that influences the cost and quality of private label cosmetics. The demand for natural and innovative ingredients has driven up costs in the cosmetics industry. 例えば, sourcing organic shea butter or rare plant extracts requires significant investment. さらに, compliance with FDA guidelines and other regulatory standards adds to the cost of raw materials.

Building strong supplier partnerships can help you manage these challenges. Reliable suppliers provide high-quality ingredients and ensure transparency regarding their sourcing practices. This transparency builds trust with your customers and helps you avoid legal risks. Partnering with suppliers who prioritize quality control and regulatory compliance ensures your products meet safety standards without unnecessary expenses.

To further optimize costs, consider sourcing ingredients in bulk or negotiating long-term contracts with suppliers. These strategies can reduce expenses while maintaining the quality of your formulations. Manufacturers like Oully, with their extensive experience in private label manufacturing, can also assist in sourcing premium ingredients at competitive prices.

パッケージデザイン, Material Choices, and Sustainability

Packaging is more than just a container for your product—it’s a key factor in consumer perception and environmental impact. The materials you choose for packaging influence both the cost and the sustainability of your private label cosmetics. 例えば, eco-friendly options like glass, recycled plastics, or biodegradable materials often cost more upfront but appeal to environmentally conscious consumers.

Sustainable packaging reduces waste and supports a circular economy. Many households produce significant amounts of plastic waste annually, making eco-friendly packaging a priority for modern brands. By investing in sustainable materials, you not only reduce your carbon footprint but also enhance your brand’s reputation as a socially responsible business.

Packaging design also affects costs. Intricate designs or premium materials may increase expenses but can elevate your product’s perceived value. Striking a balance between aesthetics, functionality, and sustainability is essential. Collaborating with manufacturers who offer customizable packaging solutions can help you achieve this balance without overspending.

Production Processes and Manufacturing Efficiency

Efficient production processes are essential for maintaining the balance between cost and quality in private label cosmetics. Streamlined manufacturing not only reduces expenses but also ensures consistent product quality, which is critical for building trust in your brand.

The Role of Advanced Manufacturing Techniques

Modern manufacturing techniques can significantly improve efficiency. Automated systems, 例えば, reduce human error and speed up production. These systems ensure that every batch of cosmetics meets the same high standards, which is vital for customer satisfaction. さらに, technologies like precision mixing and filling machines help optimize ingredient usage, minimizing waste and lowering costs.

ヒント: Partner with manufacturers who use state-of-the-art equipment. This ensures your products are made with precision and consistency.

Importance of Quality Control in Production

Quality control is a cornerstone of efficient manufacturing. Regular testing during production helps identify and resolve issues before they escalate. 例えば, testing the viscosity of a lotion or the pH level of a cleanser ensures the final product performs as expected. By catching problems early, you avoid costly recalls or customer complaints.

Manufacturers like Oully implement rigorous quality control measures at every stage of production. This includes inspecting raw materials, monitoring production lines, and testing finished products. Such practices guarantee that your cosmetics meet regulatory standards and customer expectations.

Batch Sizes and Cost Efficiency

The size of your production batches directly impacts costs. Larger batches often reduce the cost per unit, making them more economical. しかし, producing in smaller batches allows you to test new formulations or cater to niche markets without overcommitting resources.

Finding the right balance is key. Start with smaller batches to gauge market demand. Once your brand gains traction, scale up production to maximize cost efficiency. Manufacturers offering flexible batch sizes can help you adapt to changing market needs without compromising quality.

Sustainable Practices in Manufacturing

Sustainability is becoming a priority for many cosmetic brands. Eco-friendly production processes not only reduce environmental impact but also appeal to conscious consumers. 例えば, using renewable energy sources or recycling water in manufacturing can lower costs and enhance your brand’s reputation.

注記: Consumers are more likely to support brands that align with their values. Investing in sustainable manufacturing practices can set your brand apart in a competitive market.

Collaboration with Experienced Manufacturers

Working with an experienced manufacturer simplifies the production process. Companies like Oully offer end-to-end support, from formulation to packaging. Their expertise in private label cosmetics ensures your products are made efficiently and to the highest standards. By leveraging their knowledge, you can focus on growing your brand while they handle the complexities of production.

Efficient production processes are the backbone of a successful private label cosmetic brand. By prioritizing advanced techniques, quality control, and sustainability, you can deliver high-quality products at competitive prices. This approach not only boosts profitability but also strengthens your brand’s position in the market.

Strategies for Balancing Quality and Cost

Leverage Ready-Made Formulations for Cost Savings

Using ready-made formulations can significantly reduce the costs of launching your private label cosmetics. These formulations are pre-tested and optimized, eliminating the need for extensive research and development. By choosing this approach, you can focus on branding and marketing while ensuring high-quality products that meet customer expectations.

Ready-made formulations offer several advantages:

They minimize the time and resources required for product development.

Stored recipes allow for quick product changes, enhancing production efficiency.

Intelligent process automation ensures consistent quality and reduces waste.

例えば, digital technologies in private label manufacturing streamline processes, lowering overall project costs and improving profitability. This strategy is particularly beneficial for new brands aiming to enter the market quickly without compromising on quality. By leveraging these formulations, you can allocate more resources to other critical areas, such as packaging design and customer engagement.

ヒント: Partner with experienced manufacturers like Oully, who offer a wide range of ready-made formulations. Their expertise ensures your products align with industry standards while keeping costs under control.

Negotiate with Manufacturers Like Oully for Better Pricing

Finding the right private label manufacturer is crucial for balancing quality and cost. Manufacturers like Oully provide flexible solutions tailored to your brand’s needs. Negotiating with such partners can help you secure better pricing without sacrificing quality.

When negotiating, consider the following strategies:

Discuss Bulk Orders: Larger orders often result in lower costs per unit.

Request Customization Options: Tailored solutions can align with your budget and brand vision.

Explore Long-Term Contracts: Committing to a long-term partnership may lead to discounted rates.

Private label cosmetics allow you to avoid significant investments in research and development. By collaborating with manufacturers, you can rely on their expertise to produce high-quality products that meet your specifications. This approach not only reduces costs but also ensures your brand maintains a competitive edge in the market.

注記: Transparent communication with your manufacturer is key. Clearly outline your budget and quality expectations to achieve the best results.

Optimize Batch Sizes to Reduce Costs

Batch size plays a critical role in managing costs and maintaining quality. Producing larger batches often reduces the cost per unit, making it a cost-effective option for established brands. しかし, smaller batches offer flexibility, allowing you to test new formulations or cater to niche markets.

To optimize batch sizes:

Start with smaller batches when launching your brand. This approach minimizes risk and helps gauge market demand.

Scale up production as your brand gains traction. Larger batches improve cost efficiency and profitability.

Work with manufacturers who offer flexible batch size options. This flexibility ensures you can adapt to changing market needs without overcommitting resources.

Efficient batch management also reduces waste and ensures consistent product quality. Manufacturers like Oully implement advanced production techniques to optimize batch sizes, helping you balance quality and cost effectively.

ヒント: Regularly review your production data to identify opportunities for cost savings. Adjust batch sizes based on sales trends and customer feedback.

Invest in Scalable and Efficient Manufacturing Processes

Scaling your cosmetic brand requires a thoughtful approach to manufacturing. Investing in scalable and efficient processes ensures you can meet growing demand without compromising product quality or increasing costs unnecessarily. Advanced manufacturing technologies play a pivotal role in achieving this balance.

High-performance equipment allows faster production while maintaining consistency across batches. This ensures your brand delivers reliable products that meet customer expectations.

Automated systems reduce manual errors and improve efficiency. 例えば, precision filling machines ensure accurate product quantities, minimizing waste and saving costs.

Data analytics tools help monitor production metrics in real time. These insights enable you to identify inefficiencies and optimize operations for better results.

Technology integration transforms manufacturing operations. AI-powered systems streamline workflows, reducing operational expenses and improving overall productivity. By adopting these innovations, you can scale your brand while keeping costs under control.

Maintaining quality during scaling is essential for brand reputation. Uniformity across all products reinforces customer trust and loyalty. Partnering with experienced manufacturers like Oully ensures your products meet high standards, even as production volumes increase. Their state-of-the-art facilities and expertise in private label cosmetics make them an ideal choice for brands looking to grow sustainably.

ヒント: Start small and scale gradually. Test your processes with smaller batches before committing to large-scale production. This approach minimizes risks and ensures your manufacturing systems can handle increased demand effectively.

Focus on Core Products to Streamline Operations

Focusing on your core products simplifies operations and enhances your brand’s market position. Instead of spreading resources thin across multiple formulations, concentrate on a few high-performing products that resonate with your target audience.

Core products define your brand identity. They showcase your expertise and set you apart from competitors. 例えば, if your brand specializes in natural skincare, prioritize formulations featuring organic ingredients like aloe vera or shea butter. Highlighting these products in your marketing efforts strengthens your brand’s appeal and builds customer loyalty.

Streamlining operations around core products also reduces costs. Fewer formulations mean less complexity in sourcing raw materials, managing inventory, and coordinating production. This efficiency translates into lower operational expenses and faster turnaround times.

Simplified supply chains make it easier to maintain consistent quality.

Focused production schedules improve manufacturing efficiency.

Targeted marketing campaigns maximize the impact of your promotional efforts.

Collaborating with manufacturers like Oully can further enhance this strategy. Their expertise in custom formulations and flexible production options allows you to refine your core products without overextending your resources. By leveraging their support, you can deliver high-quality cosmetics that align with your brand vision.

注記: Regularly review your product portfolio. Identify which products perform best and align with your brand’s goals. Discontinue underperforming items to free up resources for your core offerings.

Real-World Examples and Case Studies

オウリー: A Trusted Partner for Balancing Quality and Cost

Oully has established itself as a reliable partner for private label cosmetics by consistently delivering high-quality products while maintaining cost efficiency. Their FDA-, ISO-, and cGMP-certified facility ensures compliance with safety regulations, which is crucial for building trust in your brand. With flexible minimum order quantities (MOQ), Oully allows you to manage inventory effectively, reducing financial risks for your business.

Their pricing structures are designed to support profitability without compromising product quality. 例えば, Oully’s scalable manufacturing processes help lower production costs while maintaining consistency across batches. This balance enables you to offer competitive pricing to your customers while meeting their expectations for premium cosmetics.

Performance Indicator | 説明 |

|---|---|

Financial Health | Indicates the manufacturer’s ability to sustain operations and invest in quality improvements. |

Pricing Structures | Reflects the cost models that affect overall expenses and profitability for brands. |

Minimum Order Quantities (MOQ) | Determines the flexibility and financial viability of orders, impacting inventory management. |

製品品質 | Ensures that the products meet the required standards and customer expectations. |

Compliance with Safety Regulations | Validates that products are safe for consumers, which is crucial for brand reputation. |

Ooullyと提携することによって, you gain access to advanced manufacturing techniques and sustainable practices, ensuring your cosmetics align with market trends and consumer values.

Example 1: A Brand That Prioritized Quality Over Cost

One private label cosmetic brand chose to prioritize quality above all else. They invested heavily in premium ingredients, such as organic oils and rare plant extracts, to create products that stood out in the market. Their focus on quality helped them build a loyal customer base, as consumers appreciated the superior performance of their cosmetics.

しかし, this approach came with challenges. The high production costs limited their ability to scale operations and compete on price. While their products gained recognition for quality, their profitability suffered due to the lack of cost control. This case highlights the importance of balancing quality and cost to achieve sustainable growth.

Example 2: A Brand That Reduced Costs Without Compromising Quality

Another brand faced rising production costs but wanted to maintain the quality of their cosmetics. They implemented strategic measures to reduce expenses while ensuring their products met customer expectations. 例えば:

They streamlined their supply chain to eliminate inefficiencies.

They adopted advanced manufacturing technologies to enhance production efficiency.

They negotiated bulk ingredient purchases to lower costs.

Despite these cost-saving measures, the brand continued to innovate and deliver high-quality cosmetics. Their ability to balance cost and quality allowed them to remain competitive and grow their market share.

製品タイプ | Price Difference (%) | Quality Maintenance |

|---|---|---|

Canned Green Beans | 41 | First-tier quality maintained |

Canned Cling Peaches | 5 | First-tier quality maintained |

Private Label Bread | 2.4 cents per loaf | Cost-effective substitute |

This example demonstrates how strategic decisions can help you reduce costs without compromising the quality of your private label cosmetics.

Lessons Learned from Successful Private Label Cosmetic Brands

Successful private label cosmetic brands share common strategies that help them thrive in a competitive market. By studying their approaches, you can gain valuable insights to strengthen your own brand.

Focus on a Clear Brand Identity

Leading brands understand the importance of defining their identity. They choose a niche and tailor their cosmetics to meet specific customer needs. 例えば, some brands specialize in natural skincare, while others focus on luxury cosmetic products. A clear identity helps you stand out and attract loyal customers.Prioritize Customer Feedback

Successful brands actively listen to their customers. They use feedback to improve their cosmetics and address concerns. This approach builds trust and ensures your products align with customer expectations. Regular surveys or reviews can provide insights into what your audience values most.Invest in Quality Without Overspending

High-performing brands balance quality and cost effectively. They work with reliable manufacturers to source premium ingredients at competitive prices. This ensures their cosmetics meet high standards without straining their budget. You can adopt this strategy by partnering with experienced manufacturers like Oully.Leverage Marketing to Build Trust

Marketing plays a key role in the success of private label cosmetics. Brands that highlight their unique selling points, such as sustainable packaging or cruelty-free formulations, often gain customer loyalty. Clear communication about your brand values can set you apart from competitors.Adapt to Market Trends

The best brands stay ahead by adapting to trends. Whether it’s eco-friendly packaging or innovative formulations, they evolve to meet changing consumer demands. Staying informed about industry developments can help you keep your brand relevant.

By applying these lessons, you can position your private label cosmetic brand for long-term success. Focus on building trust, maintaining quality, and staying adaptable to create a strong presence in the market.

Balancing quality and cost is the cornerstone of a successful private label cosmetic brand. Understanding the cost-quality tradeoff helps you make informed decisions when launching your brand. Factors like ingredient selection, パッケージング, and manufacturing efficiency play a critical role in achieving this balance. 包装, for instance, combines form, function, and sustainability, enhancing consumer connection and brand storytelling. High-quality materials can also positively influence purchasing decisions.

Applying these strategies ensures your cosmetics meet customer expectations while controlling costs. This balance not only supports profitability but also builds a sustainable and reputable brand. By focusing on quality and cost, you create cosmetics that resonate with your audience and secure long-term success.

よくある質問

What is the most cost-effective way to start a private label cosmetic brand?

Begin with ready-made formulations. These pre-tested recipes save time and money while ensuring high-quality products. Focus on a few core products to streamline operations and reduce complexity. Partnering with experienced manufacturers like Oully can also help you manage costs effectively.

How can I ensure my cosmetics meet quality standards?

Work with manufacturers who follow strict quality control measures. Look for certifications like FDA, ISO, またはcGMP. Regularly test your products for safety and performance. Using high-quality ingredients and advanced manufacturing techniques ensures your cosmetics meet customer expectations.

Is sustainable packaging worth the extra cost?

はい, sustainable packaging appeals to eco-conscious consumers and enhances your brand’s reputation. While it may cost more upfront, it can lead to increased customer loyalty and long-term profitability. Choose materials like recycled plastics or biodegradable options to align with market trends.

How do I choose the right manufacturer for my brand?

Select a manufacturer with a proven track record in private label cosmetics. Look for certifications, flexible MOQs, and end-to-end support. Manufacturers like Oully offer customizable solutions and advanced facilities, ensuring your products meet both quality and cost requirements.

Can I reduce costs without compromising product quality?

はい, you can. Negotiate bulk ingredient purchases, optimize batch sizes, and adopt efficient manufacturing processes. Partnering with experienced manufacturers helps you maintain quality while managing costs. Focus on balancing these factors to build a sustainable and profitable brand.